The main academic and professional missions are to:

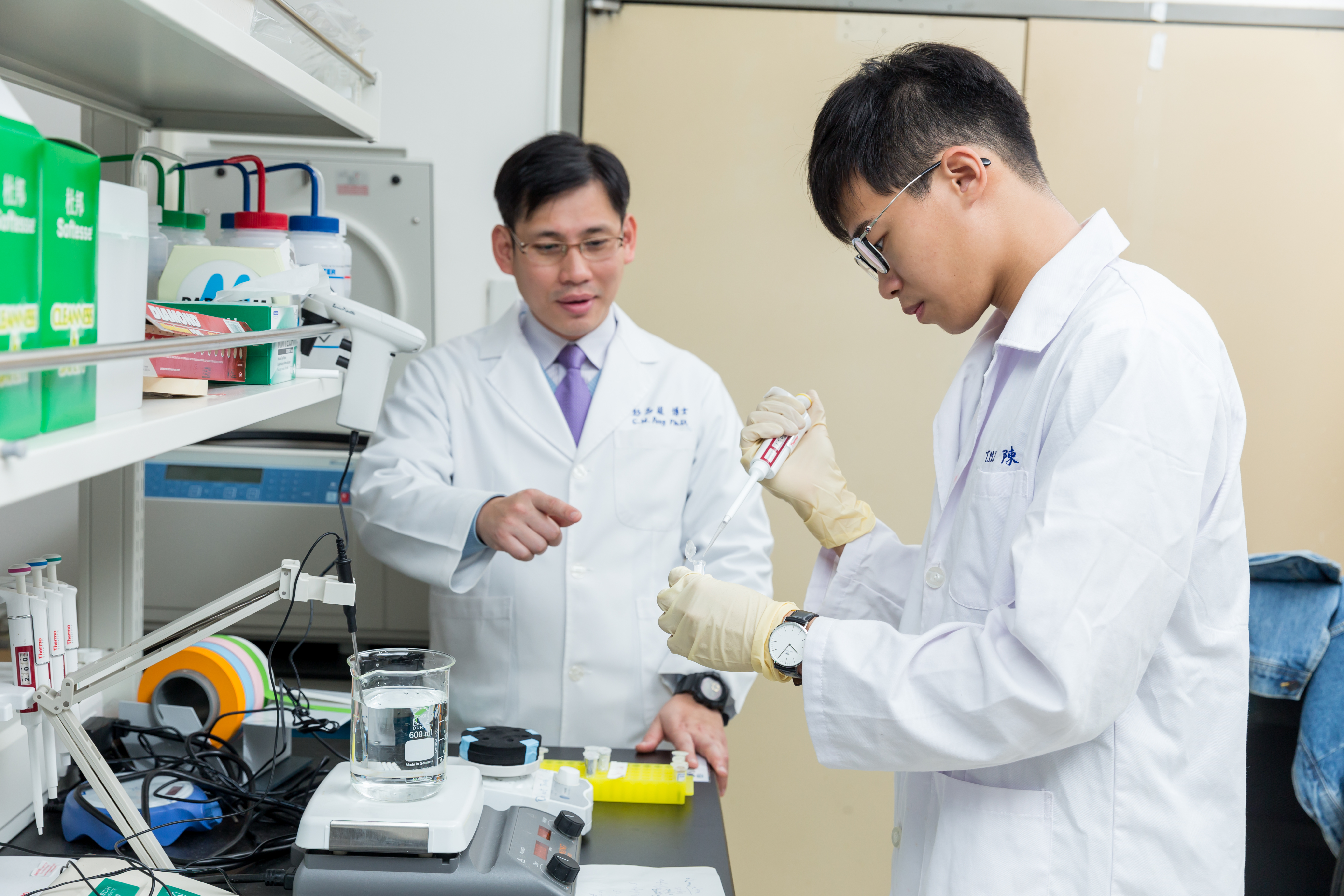

• Enhance students' basic knowledge and professional skills in biomedical engineering and have the competence to integrate multidisciplinary technologies.

• Educate student to comprehensively specialize in the field of biomedical engineering by hands-on and clinic problem-based oriented teaching approaches.

• Foster student with humanities and noble character for the promotion of social care and social well-being.

• Nurture student to be an innovative biomedical engineer with prospective and international vision.

Teaching Facility and Room Scheduling

In Space for teaching purposes, we plan to create 3 teaching laboratories in the upcoming year. With fully support from our administration, we will get appropriate space soon and start our new labs, including the maker lab, the medical mechanics and materials lab, and the bio-photomechatronics lab.

Maker Lab (ML)

Purpose: Maker Lab is a fully equipped shared maker space & education center focusing on the application of digital fabrication technologies towards prototyping IoT, smart devices, and hardware products. Our lab provides a platform for makers, clinicians and manufacturers to explore the power of prototyping with digital fabrication technologies. It enables our students to bring their early stage concepts to working prototypes faster and more efficiently. It will improve understanding how to transform our concepts into life and in turn, facilitating SBME to becoming a destination for hardware product innovations. Total space includes evacuation path, reception area, lounge bar, store room, demonstration area, workshop, supply, class room and conference room.

Facilities:

Software: Solidworks, AutoCAD, LabVIEW; hardware: Arduino, Raspberry Pi, Video, Audio, Projector, Vinyl Cutter and 3D printer.

Associated Courses: Individual Studies, Human Factors Engineering, Practices of medical device design

Lab of Medical Mechanics & Materials (L3M):

Purpose: Train students to understand the material mechanical properties, test methods, the principle of the test equipment and conditions set production and observation of the metallographic specimens. Materials Structure and mechanical properties.

Facilities:

Drill Press: The REXON DP17F Drill Press is a typical floor mounted 16-inch drill press. It is used to drill holes in all kinds of wood, plastic, and metal and can be used with a variety of tools.

Material Testing Machine: GOTECH AI-7000M Universal Testing Machine. Function: Test machine for material analysis in static mode. Screw vertical actuator. Force cells range from 200 N to 5 kN.

Simulation System of Biomechanics: LS-DYNA is an advanced general-purpose multiphysics simulation software package developed by the Livermore Software Technology Corporation (LSTC). LS-DYNA is used by the automobile, aerospace, construction, military, manufacturing, and bioengineering industries.

Body Scanner: 3D Pandora

3D printer: Home 3D printers mostly use a process called, alternately, filament deposition manufacturing (FDM) or fused filament fabrication (FFM). A plastic, nylon or similar filament is melted and then deposited onto a smooth surface (called the print bed) by the printer extruder. Printing on your own will make things much more affordable in the long run. Plus you get the fun of watching your design manifest in front of your own eyes.

Instron 8511 with MTS TestStar2 control: Test machine for material analysis in static and dynamic mode, Hydraulic vertical actuator, Electronic torsional actuator, Force cells range from 250 N to 20 kN, Torque cells from 20 Nm to 100 Nm, Environmental chamber with e.g. 37ºC saline solution, Ringers solution or similar.

Color, Multi-material 3D printer: Connex3 was the first 3D printer in the world to simultaneously 3D print multiple colors and materials. 20-85 micron for features below 50 mm; up to 200 micron for full model size.

Five-axis machining: When machining unique medical devices used to administer radiation treatments for cancer patients, high quality and fast turnaround is of utmost importance.

Lab of Bio-Optomechatronics (LBO):

Purposes: fabrication and performance measurement of micro/nano optomechatronics devices. Microcomputer programming and application. Development of novel physical sensors and actuators. Development of vibration control systems. Design of electro-mechanical devices. Introduction for student what is measurement and measurement system. Image analysis and processing.

Facilities:

Microcomputer control: Electric motor control systems, linear actuators, precision multi-meters, precision multi-function generators, digital oscilloscopes, microcontroller development systems.

Measurement system: Hammer, Personal computer, Power supply, Processor, Workbench, Signal generator, Signal storage system, Autocontrol system, Oscilloscope, Force control servo drive, Non-contact displacement measurement, Temperature controllers.

Optical Metrology: Image analysis and processing equipment, object-glass, indicator, air conditioner, PC, Projector, image system, Notebook, oscilloscope, magnet base, opto-isolator, MATHCAD11, 45W fiber laser, Precision Linear Rails, laser power Training the ability of precision processing and measurement of student supply, He-Ne laser.

Prospects after Graduation: